Top Tips for Designing and Building Your Own Aluminum Boat

Top Tips for Designing and Building Your Own Aluminum Boat

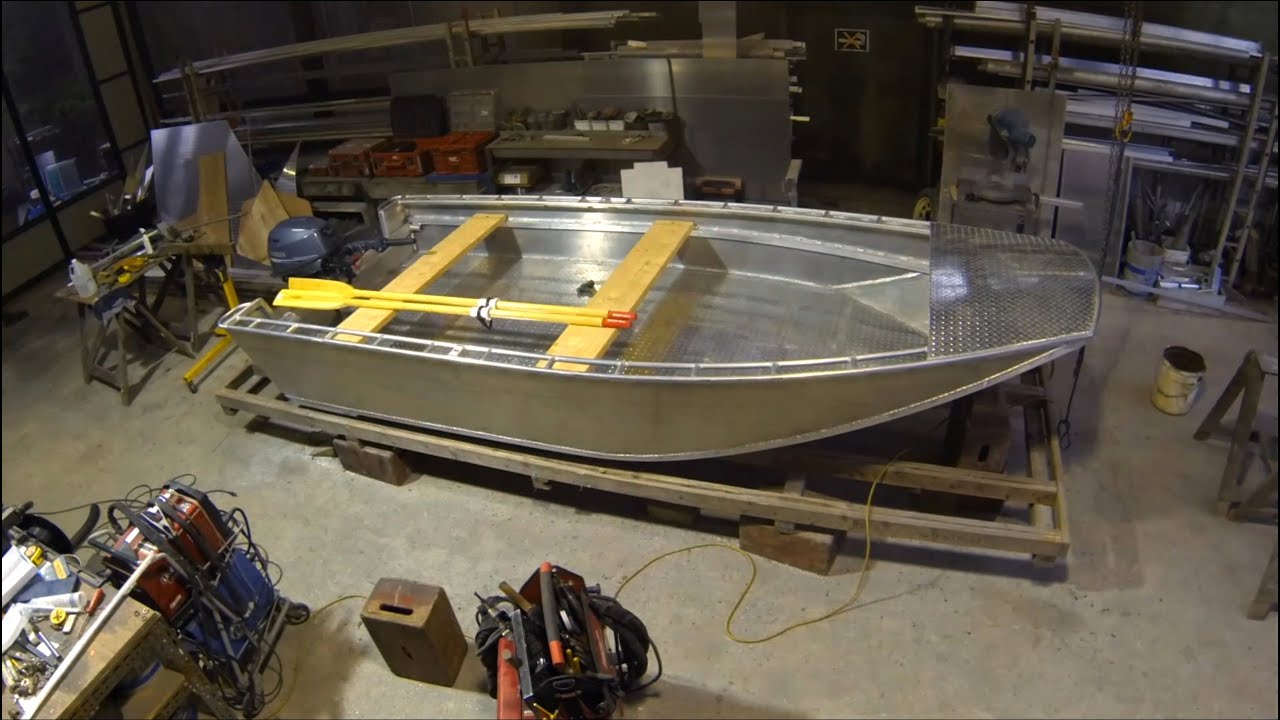

Building your own aluminum boat is a rewarding challenge that allows you to create a vessel tailored to your specific needs and preferences. From navigating serene lakes to tackling rugged rivers, an aluminum boat provides durability, versatility, and a unique sense of accomplishment. This comprehensive guide outlines essential tips for designing and building your own aluminum boat, ensuring a successful and enjoyable experience.

Planning and Design

Determine Your Needs and Purpose

Before diving into the design phase, clearly define the purpose of your boat. Consider the following factors:

- Intended Use: Fishing, hunting, recreational cruising, or a combination thereof?

- Water Conditions: Calm lakes, rough rivers, or open ocean?

- Desired Size and Capacity: Number of passengers and cargo weight?

- Power Requirements: Outboard engine, electric motor, or other propulsion system?

Research and Gather Inspiration

Explore various aluminum boat designs, both online and in person. Analyze successful models and consider their strengths and weaknesses. Studying existing boats will inspire your own design and highlight key elements to incorporate.

Sketching and Design Software

Start by sketching rough ideas on paper to capture your initial vision. As your design evolves, utilize computer-aided design (CAD) software, such as SolidWorks or Fusion 360, for detailed 2D and 3D modeling.

Hydrostatic Calculations and Stability

Ensure your boat design is inherently stable and meets safety regulations. Utilize online hydrostatic calculators or software to calculate buoyancy, displacement, and stability parameters. Consider the following:

- Center of Gravity: Carefully position the boat's weight distribution to achieve optimal balance.

- Metacentric Height: This measurement determines the boat's initial stability when disturbed from equilibrium.

- Freeboard: Adequate freeboard provides protection from waves and ensures watertight integrity.

Materials and Construction

Aluminum is a popular choice for boat building due to its strength, lightweight properties, and resistance to corrosion. Consider the following factors when selecting materials:

- Aluminum Alloy: 5052 and 6061 are common alloys used in boat construction. Choose an alloy with suitable strength-to-weight ratio for your intended application.

- Sheet Thickness: Determine the required thickness based on the boat's size, intended use, and anticipated stress levels.

- Joining Methods: Aluminum can be joined using welding, riveting, or a combination of both. Choose a method that suits your skills and equipment.

Building Process

Creating the Frame

The frame provides the boat's structural support and shape. Depending on your design, you might use:

- Transom: This is the rearmost support that houses the engine. It must be robust enough to withstand the engine's thrust.

- Stringers: Longitudinal supports that run along the boat's length, providing stability and rigidity.

- Flooring: Cross-sectional supports that connect stringers and provide a base for the deck.

Aluminum Sheeting

Once the frame is assembled, carefully measure and cut aluminum sheets to form the hull, deck, and other components. Employ precise cutting tools like shears, plasma cutters, or water jets for clean and accurate results.

Joining and Welding

Securely join the aluminum sheets using welding or riveting. Welding requires expertise and proper safety precautions. Consider the following tips:

- Welding Technique: Use a TIG (Gas Tungsten Arc Welding) or MIG (Gas Metal Arc Welding) welding process.

- Filler Metal: Select filler metal with a similar chemical composition to the aluminum alloy used in the boat.

- Joint Preparation: Ensure clean and properly aligned joints for successful welding.

Finishing and Refinement

Once the hull and deck are assembled, sand and polish the surfaces to a smooth finish. Apply primer and paint for corrosion protection and aesthetics. Consider the following steps:

- Sanding: Use progressive grits of sandpaper to remove any imperfections and prepare the surface for painting.

- Priming: Apply a high-quality primer to create a smooth, uniform surface for the paint.

- Painting: Choose marine-grade paint designed for aluminum boats. Apply multiple coats for optimal protection and durability.

Essential Considerations

Safety and Regulations

Prioritize safety throughout the design and building process. Adhere to all local and national boating regulations regarding safety equipment, lighting, and buoyancy.

Stability Testing

Before launching your boat, perform thorough stability tests in a controlled environment. Load the boat with simulated weight to ensure it remains stable under various conditions.

Engine Installation and Propeller Selection

Properly install the engine according to the manufacturer's specifications. Choose a propeller with the appropriate pitch and diameter for optimal performance.

Maintenance and Care

Regularly inspect and maintain your aluminum boat to preserve its integrity. Wash and rinse the boat after each use to prevent corrosion.

Conclusion

Designing and building your own aluminum boat is a rewarding journey that combines technical skills, creativity, and a passion for boating. By following these tips, you can embark on a successful project that will bring years of enjoyment on the water. Remember to prioritize safety, meticulous planning, and quality craftsmanship to create a durable and reliable vessel that you can proudly call your own.

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.